量子效率测试仪

PL/EL一体机

Sinton硅片少子寿命测试仪

Sinton硅块少子寿命测试仪

绒面反射率测试仪

3D共聚焦显微镜

在线四探针方阻测试仪

全自动扫描四探针方阻测试仪

在线薄膜厚度测试仪

晶化率测试仪

Horiba显微共焦拉曼光谱仪

傅里叶红外光谱仪

霍尔效应测试仪

分光光度计

全光谱椭偏仪

Horiba椭圆偏振光谱仪

TLM接触电阻率测试仪

超景深显微镜

网版智能影像测量仪

全自动影像测量仪

卧式拉力机

电池片稳态光衰老化试验箱

电池片紫外老化试验箱

电池片拉脱力综合测试仪

外观检验台

湿漏电测试系统

组件实验室EL测试仪

紫外老化试验箱

稳态光衰老化试验箱

电流连续性监测系统

PID测试系统

旁路二极管测试系统

LeTID测试系统

反向电流过载系统

脉冲电压测试系统

绝缘耐压测试仪

接地连续性测试仪

绝缘耐压接地测试仪

湿热环境试验箱

湿冻环境试验箱

热循环试验箱

动态机械载荷测试机

静态机械载荷测试机

冰雹冲击试验机

引出端强度试验机

霰弹冲击试验机

抗划伤(切割)测试机

剥离试验机

万能材料试验机(单臂)

万能材料试验机(双臂)

光伏玻璃透过率测试仪

醋酸测试试验箱

交联度测试系统

二极管接线盒综合测试仪

落球冲击试验机

半自动四探针

全自动探针式台阶仪

多通道太阳能MPPT系统

Horiba稳瞬态荧光光谱仪

大面积钙钛矿方阻椭偏二合一测试仪

大面积钙钛矿影像显微二合一监测站

钙钛矿P1激光划线测试仪

钙钛矿在线PL测试仪

钙钛矿在线方阻测试仪

钙钛矿在线膜厚测试仪

钙钛矿工艺检测工作站

手持式IV测试仪

便携式EL测试仪

手持热成像测试仪

户外组件多通道测试系统

光伏逆变器电能质量测试仪

无人机EL检测仪

IV测试仪

IVEL分选机

沉积温度和溅射功率对ITO薄膜性能的影响研究

日期:2024-03-01浏览量:250

ITO薄膜在提高异质结太阳能电池效率方面发挥着至关重要的作用,同时优化ITO薄膜的电学性能和光学性能使太阳能电池的效率达到最大。沉积温度和溅射功率也是ITO薄膜制备过程中的重要参数,两者对ITO薄膜的电阻率和透过率有极大影响。美能扫描四探针方阻测试仪能够帮助用户优化太阳能电池的电学特性,美能分光光度计支持紫外至近红外区域测定,开启光学检测新未来!本篇文章将给大家讲解沉积温度和溅射功率对ITO薄膜的电学和光学性能的影响。

沉积温度

1.电学性能

沉积温度通过改变生长过程中的微观结构来影响ITO薄膜的性能。随着沉积温度的升高,载流子浓度先增大后减小,因为沉积温度升高时Sn4+更有利于取代In3+,从而增加载流子。当温度为190℃时,载流子浓度降低,这是由于Sn在高温下能与O2充分反应,生成复合化学计量比比较完整的氧化物,导致载流子浓度降低。然而,迁移率随着沉积温度的升高而增加,并在270℃时达到最大值。原因是沉积温度的升高提高了结晶度,这有助于提高迁移率。

沉积温度影响ITO薄膜的电学特性

2.光学性能

ITO薄膜的透过率随着沉积温度的升高而增加,在270℃时达到最大值90.9%。一方面,Sn4+在高沉积温度下更有利于取代In3+,从而生成较少的低价棕色氧化物,从而提高可见光透过率。另一方面,它可以提高高沉积温度下的结晶度。

沉积温度影响ITO薄膜的光学特性

溅射功率

溅射功率对ITO薄膜的导电性能也有非常重要的作用,进而通过影响溅射粒子的能量来影响ITO薄膜的致密性以及与硅片之间的附着力。

1.电学性能

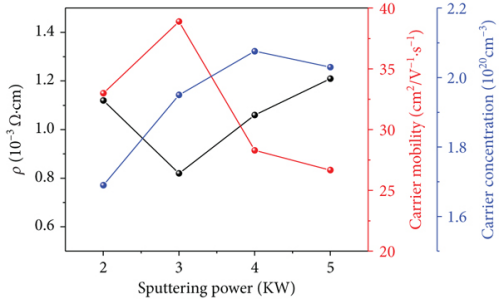

溅射功率影响ITO薄膜的电学特性

从上图可以看出,载流子浓度随着溅射功率的增加而增加。由于较高的溅射功率会产生大量的溅射颗粒,在相同氧含量下,氧气不足以充分氧化溅射颗粒,从而使载流子浓度增加。随着溅射功率的增大,迁移率先增大后减小。随着溅射功率的增加,氩离子可以获得更高的能量,有利于提高ITO薄膜与衬底之间的附着力,从而改善薄膜的晶体结构,载流子迁移率进一步提高。然而,当溅射功率继续增加时,薄膜会受到损伤,载流子迁移率会降低,因此ITO薄膜的电阻率随着溅射功率的增加先下降后上升。另外,溅射功率不应超过阈值。一方面,如果溅射功率过高,高能粒子会对薄膜造成损伤,进一步影响薄膜的导电性能。另一方面,陶瓷靶材脆性大,用大功率轰击很容易导致断裂。

2.光学性能

随着溅射功率的增加,ITO薄膜的透过率先增大后略有减小。溅射粒子在低溅射功率下受到限制,溅射粒子可以被氧气完全氧化,生成高电阻、透明的氧化物;因此,透过率可以达到90%以上。然而,随着溅射功率的增加,溅射颗粒数量增加,在氧含量不变的情况下,只有部分颗粒被氧化,导致ITO薄膜的透过率下降。另外,随着溅射功率的增加,载流子浓度达到最大值,导致透过率下降。

溅射功率影响ITO薄膜的光学特性

美能扫描四探针方阻测试仪FPP230A

联系:400-008-6690

美能扫描四探针方阻测试仪可以对最大230×230mm的样品进行快速、自动的扫描,获得样品不同位置的方阻/电阻率分布信息,可广泛应用于光伏、半导体、合金、陶瓷等诸多领域。

● 超高测量范围,测量1mΩ~100MΩ

● 高精密测量,动态重复性可达0.2%

● 全自动多点扫描,多种预设方案亦可自定义调节

● 快速材料表征,可自动执行校正因子计算

美能分光光度计UVN2800

联系:400-008-6690

美能分光光度计支持测定从紫外区到近红外区的广范围波长区域的太阳光透过率,为太阳电池的效率分析提供了有力支持。设备采用独特的双光束光学设计,可以完美地校正不同样品基质的吸光度变化,从而可稳定地进行样品的测定,具有测试范围广、精度高以及稳定性好的优点。

● 采用双光源双检测器设计,波长范围190-2800nm

● 双光栅光学结构、有效降低杂散光

● 积分球直径可达100mm,长期使用不发黄变性、光学性能稳定

ITO薄膜具有优异的电导率、透过率和反射率,其性能由制备工艺决定。高效率、低成本始终是光伏行业追求的目标,美能光伏愿帮助用户在太阳能电池的电学性能和光学性能技术优化上不断突破、创新,实现更高的电池转换效率,与用户一起在光伏行业技术发展的道路上奋力前行。

本篇文章部分内容引用:

Guoping Huang, Guixiang Zhao, Xixi Huang, Hao Zhuang, Zhongjian Zhang, Ronggang Gao, Fengxian Xie, "Influence of Deposition Parameters of ITO Films on the Performance of HJT Solar Cells", International Journal of Photoenergy, vol. 2023, Article ID 1065503, 8 pages, 2023. https://doi.org/10.1155/2023/1065503