量子效率测试仪

PL/EL一体机

Sinton硅片少子寿命测试仪

Sinton硅块少子寿命测试仪

绒面反射率测试仪

3D共聚焦显微镜

在线四探针方阻测试仪

全自动扫描四探针方阻测试仪

在线薄膜厚度测试仪

晶化率测试仪

Horiba显微共焦拉曼光谱仪

傅里叶红外光谱仪

霍尔效应测试仪

分光光度计

全光谱椭偏仪

Horiba椭圆偏振光谱仪

TLM接触电阻率测试仪

超景深显微镜

网版智能影像测量仪

全自动影像测量仪

卧式拉力机

电池片稳态光衰老化试验箱

电池片紫外老化试验箱

电池片拉脱力综合测试仪

外观检验台

湿漏电测试系统

组件实验室EL测试仪

紫外老化试验箱

稳态光衰老化试验箱

电流连续性监测系统

PID测试系统

旁路二极管测试系统

LeTID测试系统

反向电流过载系统

脉冲电压测试系统

绝缘耐压测试仪

接地连续性测试仪

绝缘耐压接地测试仪

湿热环境试验箱

湿冻环境试验箱

热循环试验箱

动态机械载荷测试机

静态机械载荷测试机

冰雹冲击试验机

引出端强度试验机

霰弹冲击试验机

抗划伤(切割)测试机

剥离试验机

万能材料试验机(单臂)

万能材料试验机(双臂)

光伏玻璃透过率测试仪

醋酸测试试验箱

交联度测试系统

二极管接线盒综合测试仪

落球冲击试验机

半自动四探针

全自动探针式台阶仪

多通道太阳能MPPT系统

Horiba稳瞬态荧光光谱仪

大面积钙钛矿方阻椭偏二合一测试仪

大面积钙钛矿影像显微二合一监测站

钙钛矿P1激光划线测试仪

钙钛矿在线PL测试仪

钙钛矿在线方阻测试仪

钙钛矿在线膜厚测试仪

钙钛矿工艺检测工作站

手持式IV测试仪

便携式EL测试仪

手持热成像测试仪

户外组件多通道测试系统

光伏逆变器电能质量测试仪

无人机EL检测仪

IV测试仪

IVEL分选机

美能光伏科普 | 解锁钙钛矿太阳能电池的独特优势

日期:2023-07-24浏览量:335

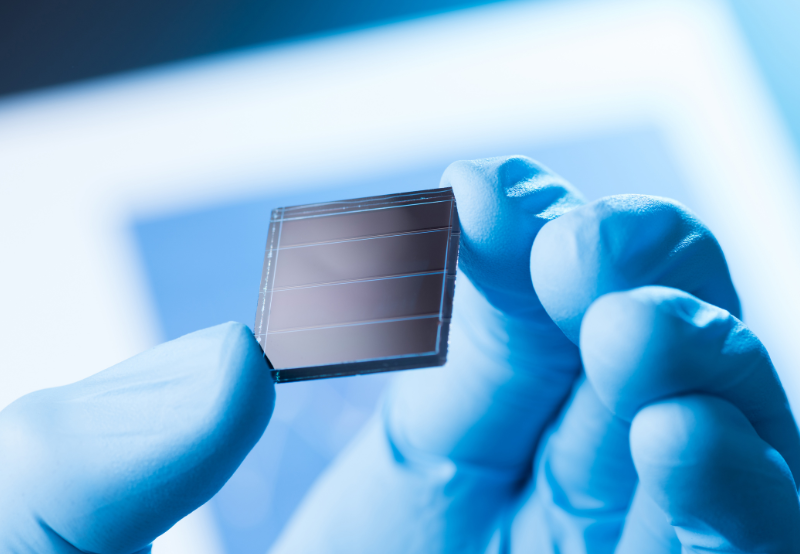

太阳能电池是一种利用光生伏特效应使太阳能转化为电能的一种光电半导体薄片,在太阳能电池发展的数十年内,种类得到了极大的丰富。其中钙钛矿(CaTiO3)受到了全球学术界和产业界的广泛关注。由「美能光伏」所研发的探针式台阶仪,通过对钙钛矿太阳能电池片薄膜表面不同位置的多点自动测量,为用户提供精确的薄膜厚度。本期「美能光伏」将给您介绍钙钛矿太阳能电池的独特优势!

![]()

为什么选择钙钛矿?

钙钛矿太阳能电池是第三代新型太阳能电池,是最具有潜力和颠覆性的新一代光伏技术。其中的钙钛矿材料ABX3是有机金属卤化物,具有非常优异的光电性质,同时具有能量转换效率高、材料成本低、应用前景广阔等优点。

![]()

高效的能量转换

在过去相当长一段时间里,晶硅光伏电池都是成本和效率极佳的统一体。相伴而生的,是天然矿物转化太阳能效率的局限性。29.43%的理论极限值,成为晶硅材料“一眼到头”的屏障。

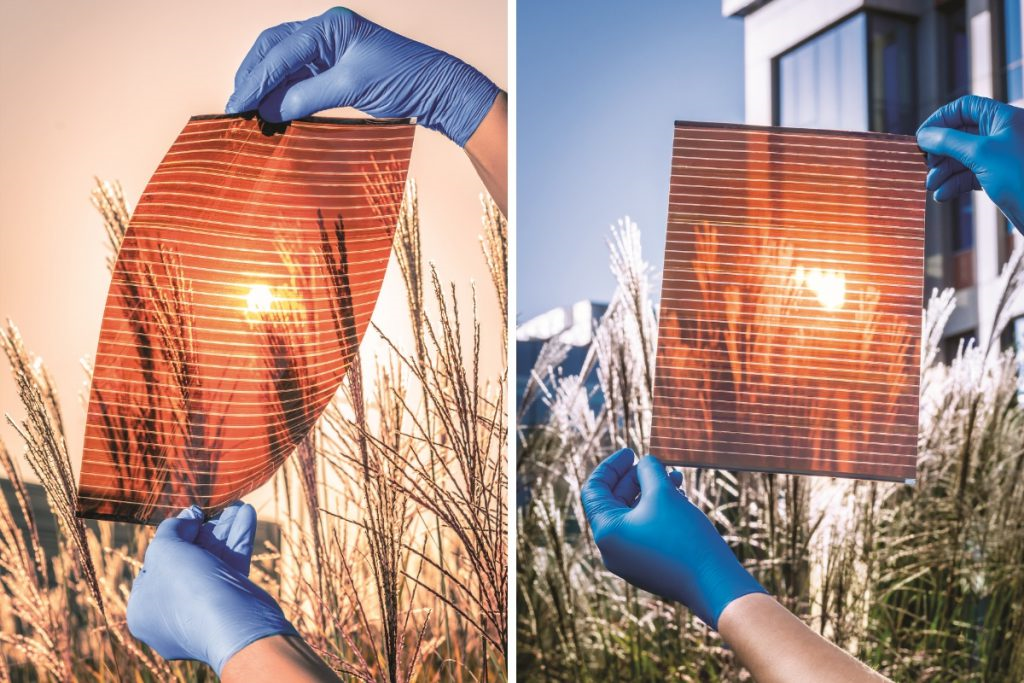

与之相比,钙钛矿的成长前景则一路高歌,今日,钙钛矿太阳能电池的实验室效率已经追平了晶硅60多年发展才达到的结果,达到了25.7%,而且钙钛矿太阳能电池的单层理论效率达33%,双层可达45%以上,具有比晶硅更高的提升空间。

钙钛矿的发展速度得益于钙钛矿材料的吸光性能,钙钛矿材料的吸光性能远强于晶硅,且在能量转换过程中具有极低的能量损失。

![]()

成本低 工艺流程短

钙钛矿太阳能电池原材料是由人工合成,且均为基础化工材料,不含有稀有元素,相对于晶硅材料来说要便宜很多。

钙钛矿的制备工艺较短,从原料的准备到进入组件成型的全过程,整个产业链可高度浓缩在一个百兆瓦的工厂里,时间控制在45分钟之内。

钙钛矿材料对杂质敏感度低、对原材料的纯度要求也低于晶硅,可以在低温状态下制备。且钙钛矿生产工艺温度不超150度,节省资源的同时还可以降低能耗,真正实现降本增速。

![]()

深远及广泛的市场前景

钙钛矿太阳能电池凭借弱光性以及颜色可定制的特点,满足了长时间发电、透光度以及美观性等市场需求,且在光伏行业以外的其他领域也拥有广泛的市场空间。

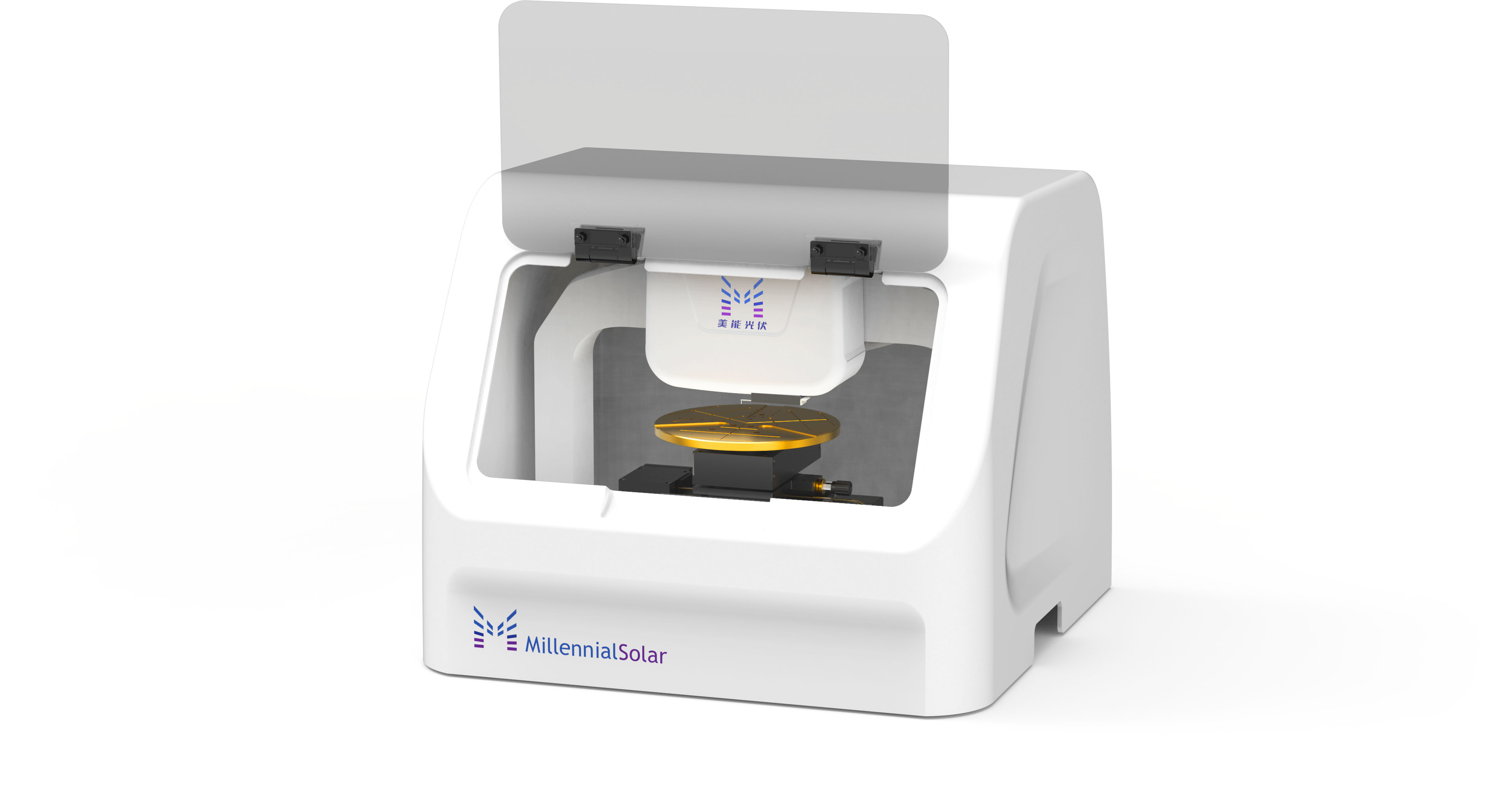

美能探针式台阶仪是一款先进的微纳测量仪器,采用了出色的仪器系统构造和最优化的测量及数据处理软件,可实现可靠、高效、简易的样品检测,应用的领域也十分广泛,可为半导体、光伏、LED、MEMS器件、材料等领域的产品提供纳米级的表面测量。

![]()

美能探针式台阶仪

SP200探针式台阶仪是一款先进的微纳测量仪器,采用出色的仪器系统构造和最优化的测量及数据处理软件,可测量表面粗糙度、波纹度、表面2D/3D形状、翘曲和应力。从而实现可靠、高效、简易的样品检测,并完成从研发到质量控制的完美把控。

在“碳中和”策略的大背景下,钙钛矿太阳能电池凭借其独特的优势,受到了众多光伏用户的一致好评。「美能光伏」将自始至终以光伏企业用户为中心,持续为光伏企业用户、光伏行业创造巨大的价值,并共同推进光伏行业稳定发展!